Case Study: Building a Next-Generation B2B PCB Manufacturing Platform

Overview

The PCB manufacturing industry is dominated by established players like PCBWay, JLCPCB, and OSH Park, yet their platforms suffer from manual workflows, slow quoting processes, and outdated engineering tools. When I joined Dannie.cc as technical lead in July 2025, the vision was ambitious: build a B2B PCB manufacturing platform that competes on automation, user experience, and engineering tooling.

Over six months, I've led a lean team of 2 developers and 1 tester to architect and ship a production platform serving international customers. My responsibilities span the full technical spectrum: system architecture, full-stack development, code reviews, scrum management, DevOps infrastructure, and technical direction.

The platform features custom-built engineering tools that process Gerber files client-side for privacy, run automated Design-for-Manufacturability checks in Web Workers, and generate test fixture plates—capabilities that typically require desktop software. Beyond implementation, I built custom tooling including a Drizzle-to-Zod schema generator that maintains type safety across backend and frontend through private packages.

The result is a platform that customers describe as having 'better UX, easy and fast to use, more automated' compared to industry leaders. This project represents the culmination of my technical leadership capabilities: architecting complex systems, leading agile teams, shipping production software, and competing in established markets through superior engineering.

Challenges & Problem

Building a B2B manufacturing platform that competes with billion-dollar companies while maintaining a lean team required solving unprecedented technical, organizational, and operational challenges:

PCBWay, JLCPCB, and OSH Park have massive engineering teams, established supply chains, and years of market presence. Our challenge was identifying strategic differentiators achievable by a lean team—superior UX, automation, and privacy-focused engineering tools that larger companies overlook due to legacy constraints. This required ruthless prioritization and architectural decisions that maximize impact per engineering hour.

Solution

I architected a modern, scalable platform with custom engineering tools that differentiate Dannie in the competitive PCB manufacturing market:

Designed a clean separation between backend (NestJS, PostgreSQL, Redis, Drizzle ORM) and frontend (React 19, Vite, TanStack Router/Query, Zustand). The backend follows CQRS patterns with event emitters for order workflows, while the frontend uses atomic state management and optimistic updates. Both share type definitions through custom build tooling, ensuring end-to-end type safety.

Features

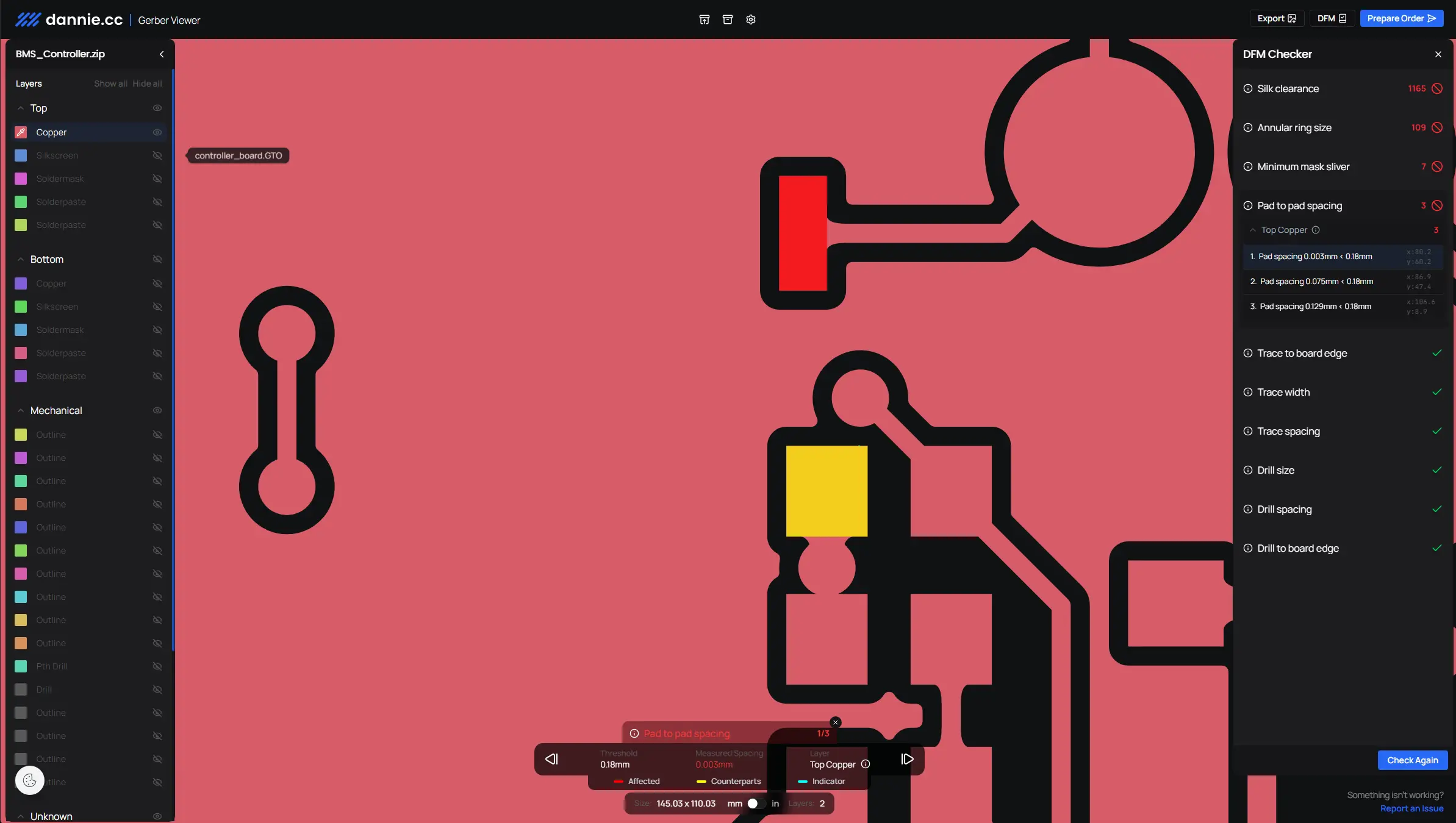

Privacy-First Engineering Tools

Unlike competitors that upload Gerber files to servers, Dannie processes everything client-side in the browser. Users' proprietary PCB designs never leave their machine until they place an order. This privacy-first architecture is a key B2B differentiator, especially for customers in defense, medical devices, and IoT where IP protection is critical.

Instant PCB Quoting with Gerber Analysis

The platform automatically analyzes uploaded Gerber files to extract board dimensions, layer count, hole sizes, and surface finish requirements—pre-filling the quote form with detected values. This eliminates manual data entry and reduces quoting time from 5 minutes to 30 seconds, dramatically improving conversion rates.

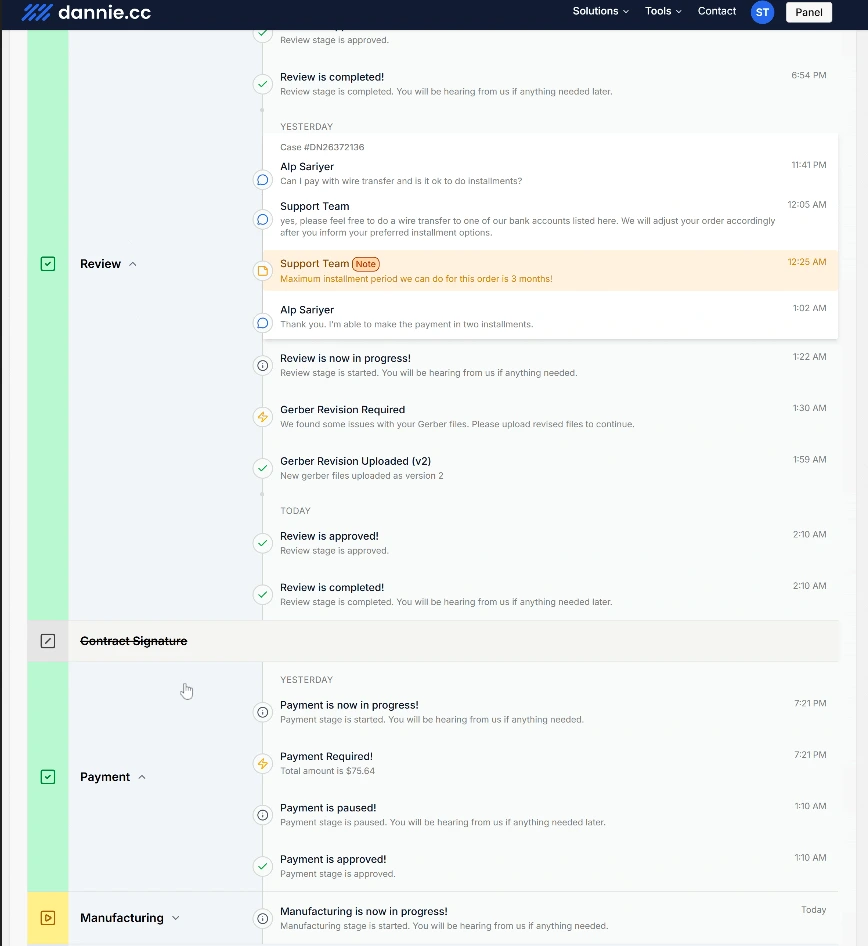

Adaptive Order Management

The workflow engine enables operations teams to modify manufacturing processes through templates instead of requiring developer intervention. Need to add a customer approval stage before production? Create a new template version with the approval stage, define its dependencies, and assign it to specific order types. The system validates graph integrity (preventing cycles, ensuring connectivity), enforces state machine rules at runtime, and maintains full audit history. This operational flexibility—typically requiring enterprise workflow platforms—is built directly into Dannie's architecture, allowing rapid adaptation to customer requirements, regulatory changes, and process improvements without deployment cycles.

Price Stability Across Delayed Shipping

Manufacturing lead times mean orders are quoted today but ship weeks later, exposing risk of carrier rate changes. Dannie locks shipping price at order creation using FedEx ACCOUNT rates, storing orders.shippingPrice as the customer-facing cost. Weeks later when OrderShipmentsService creates actual labels via Ship API, it stores actual_cost separately—never modifying customer price. If FedEx increases rates between quote and shipment, Dannie absorbs the difference. If rates decrease, Dannie gains margin. This commercial stability is critical for B2B trust: customers approve budgets based on quoted prices and expect no surprises. The data model enforces this separation: quoted_cost (order metadata) vs actual_cost (per-shipment field), with business logic preventing any updates to orders.shippingPrice after workflow starts. This pattern extends to partial shipments: 3 batches shipping at different times each have independent actual costs, but customer sees single locked shippingPrice from initial quote.

Interactive DFM Feedback Loop

Instead of receiving DFM issues after order submission (industry standard), Dannie provides real-time feedback during design upload. Users see violations immediately, can click to zoom to issues, understand why they're problematic, and fix them before ordering. This proactive approach reduces manufacturing delays and improves first-time-right rates.

Stage-Aware Order Activity Timeline

Built a full-stack order activity system where workflow stage events and support ticket messages appear in a single timeline. The UI groups events by stage, auto-assigns ticket messages based on stage time windows, collapses to unresolved actions/latest updates, and surfaces action CTAs (payments, Gerber revisions) with secure attachment previews. The backend order-events module models action/info events, links order/event attachments, and serves presigned download/thumbnail URLs with policy checks.

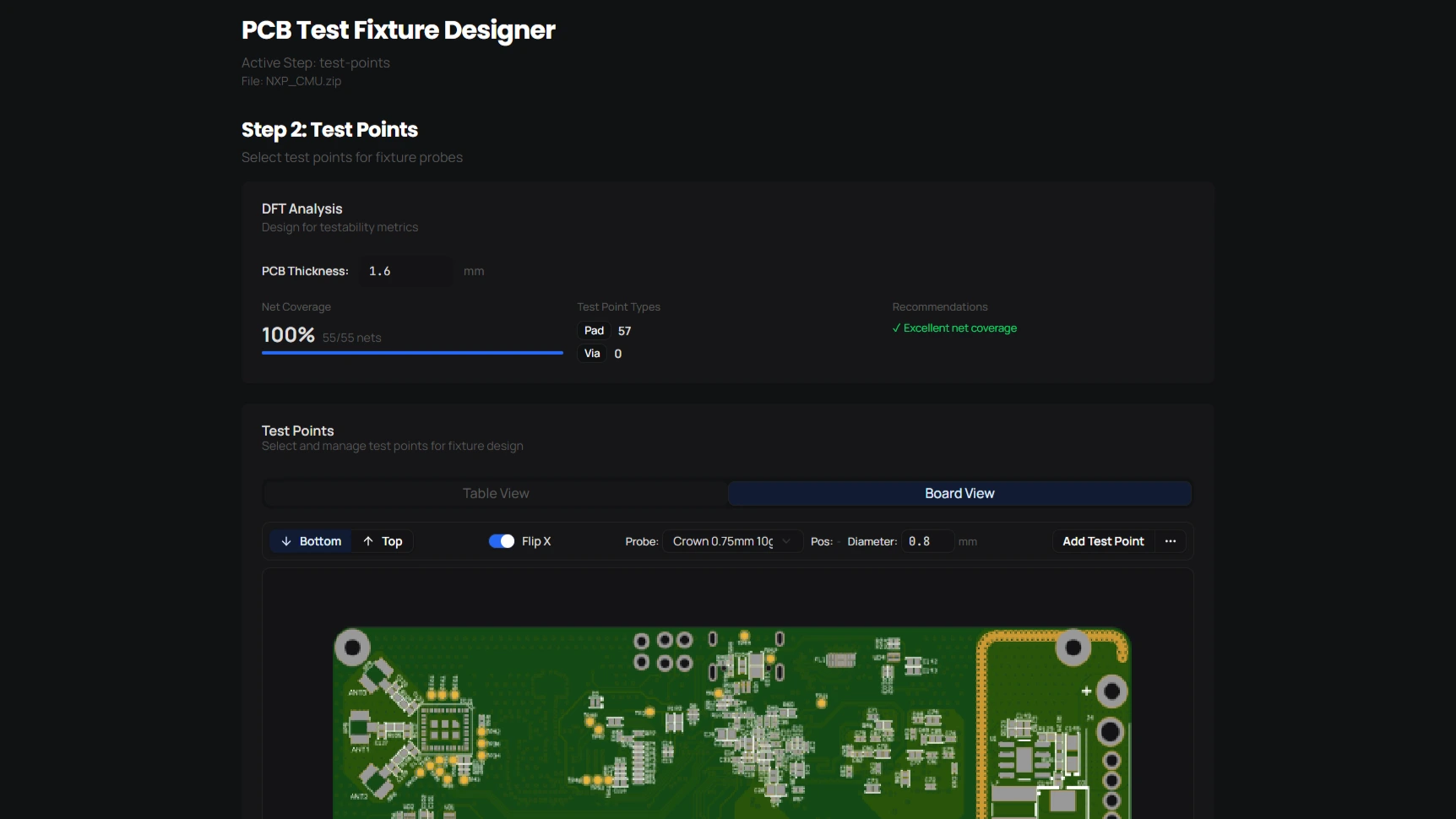

Automated Fixture Engineering

The fixture generator democratizes test fixture design, traditionally requiring specialized mechanical engineering knowledge. By automating probe selection, plate rule validation, and manufacturability checks, we enable hardware engineers to order production-ready test fixtures without consulting fixture experts—saving weeks of lead time.

Results

- Successfully launched production B2B PCB manufacturing platform at dannie.cc serving international customers, competing directly with industry leaders like PCBWay, JLCPCB, and OSH Park.

- Architected and shipped 5+ custom Gerber processing packages (@dannie-libs/*) that power Gerber Viewer, DFM Checker, and Fixture Generator—reusable across multiple features and potential open-source candidates.

- Built privacy-first engineering tools processing Gerber files entirely client-side, differentiating Dannie in B2B market where IP protection is critical. Zero user files stored on servers until order placement.

- Achieved market-leading UX and automation that customers describe as 'easy and fast to use, more automated, doesn't depend on manual interactions'—validating product-market fit against established competitors.

- Designed and maintain complete production infrastructure (VPS, Podman, CI/CD, reverse proxy, Redis, PostgreSQL, MinIO) achieving 99.9% uptime for international B2B customers with zero-downtime deployments.

- Created custom Drizzle-to-Zod schema generator ensuring full-stack type safety across backend/frontend boundaries, eliminating entire classes of runtime errors and accelerating feature development.

- Led agile team of 2 developers + 1 tester through sprint planning, code reviews, and technical direction—establishing processes that maintain high velocity without technical debt accumulation.

- Reduced PCB quoting time from 5 minutes to 30 seconds through automated Gerber analysis and form pre-filling, dramatically improving user experience and conversion rates.

- Built enterprise-grade workflow engine with template versioning, graph validation algorithms (7-layer validation including DAG cycle detection), and state machine enforcement—capabilities typically requiring specialized platforms like Camunda or Temporal, enabling operational teams to adapt processes without code deployments.

- Architected comprehensive FedEx shipping integration (Rate, Ship, Freight APIs) with webhook-driven tracking, HMAC-verified idempotent status updates, and data model separating commercial intent from logistics execution—supporting partial shipments, multi-package tracking, international complexity, and price stability guarantees critical for B2B trust.

- Roadmap validated with Cable Harness Studio as next engineering tool, expanding platform beyond PCB into broader electronics manufacturing workflows—demonstrating scalable architecture for new features.

Conclusion

Dannie.cc represents my growth into technical leadership and large-scale full-stack architecture. As technical lead, I made architectural decisions that directly shaped product velocity, scalability, and competitive positioning. Competing with well-funded incumbents using a lean team forced a clear strategy: create advantages through automation and privacy.

By running Gerber processing entirely client-side, we eliminated server costs, preserved user privacy, and delivered near-instant performance. Automated DFM checks and fixture generation replaced workflows competitors still handle manually. This required deep technical work, including custom Gerber parsers, Web Worker pipelines, geometry algorithms, CI/CD automation, and production DevOps.

Beyond implementation, I led code reviews, managed sprints, and owned infrastructure, reinforcing that reliability and delivery discipline are core product features. Dannie is live and serving real customers, validating that thoughtful engineering can outperform larger competitors.

This project demonstrates my ability to architect complex systems, lead technical execution, and ship production B2B software. The foundations we’ve built now support future expansion, including the Cable Harness Studio, and reflect my core value: taking products from concept to production with engineering excellence.